Dynamic balance system for grinding machine 3.0

Grinding wheel motion balance system is a device for measuring and correcting the unbalance of grinding wheel. Its important properties are:

1. Improved safety: Unbalanced grinding wheels can cause equipment vibration and noise, increasing the risk of machine failure and operator injury.

2. Increase productivity: The unbalanced grinding wheel will lead to unstable cutting quality and low processing accuracy, thereby reducing low productivity.

3. Extend the life of the equipment: The unbalanced grinding wheel will lead to increased wear of the equipment, thereby reducing the life of the equipment.

4. Improve product quality: The unbalanced grinding wheel will cause rough paste on the processed surface, and even leave gears, reducing product quality.

With the continuous deepening of Industry 4.0, a series of national standards and users have clear requirements for the advancement of grinding accuracy. Molitech's solution fully meets the stringent requirements for standardized measurement in the standard.

Features

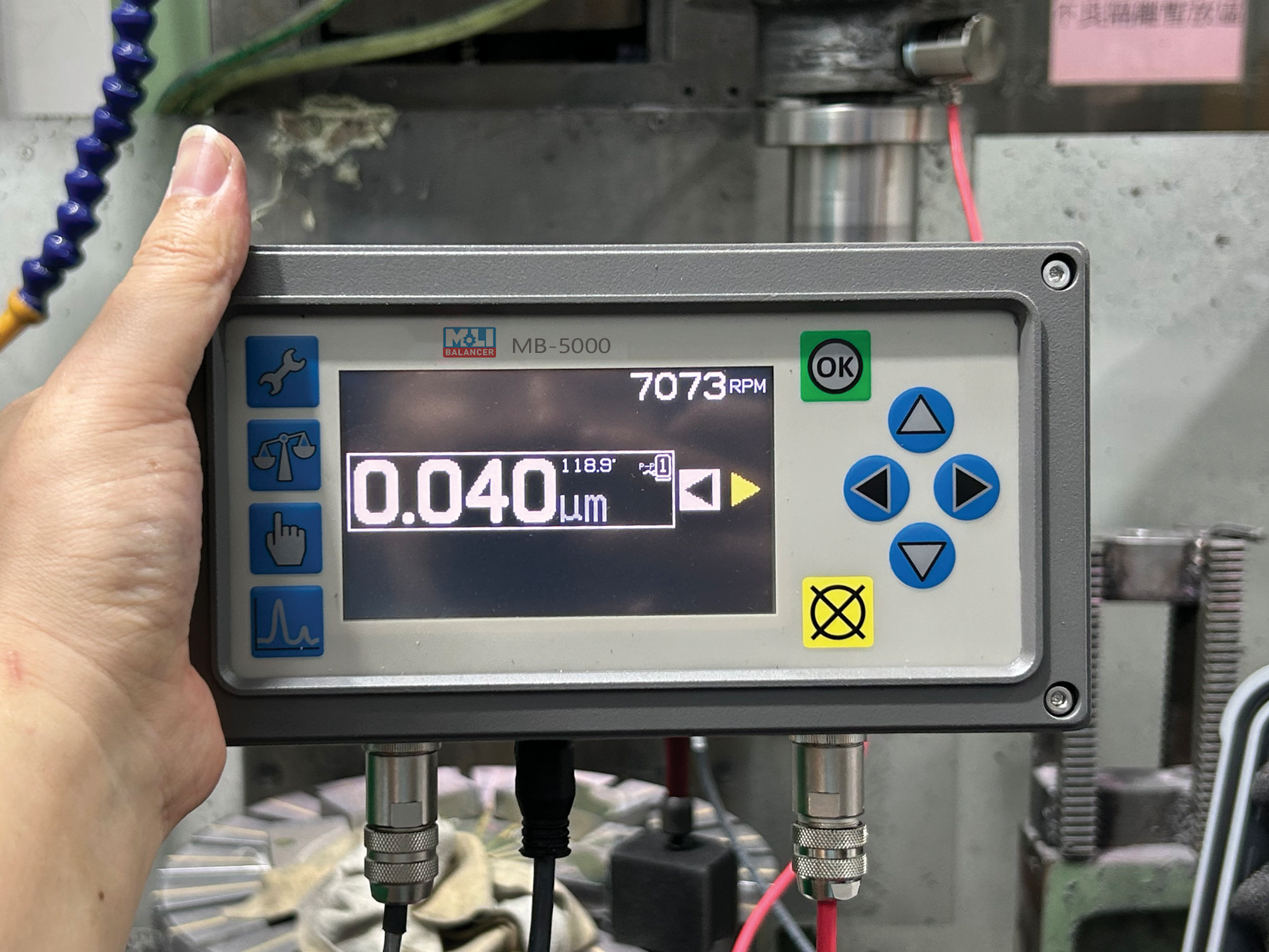

- High measurement efficiency, usually within 0.5 minutes to complete the dynamic balancing process

- High balance precision, accurate to 0.01um

- Convenient operation, touch and button combination

- Efficient integration with CNC systems

参数

A range of parameters to evaluate includes:

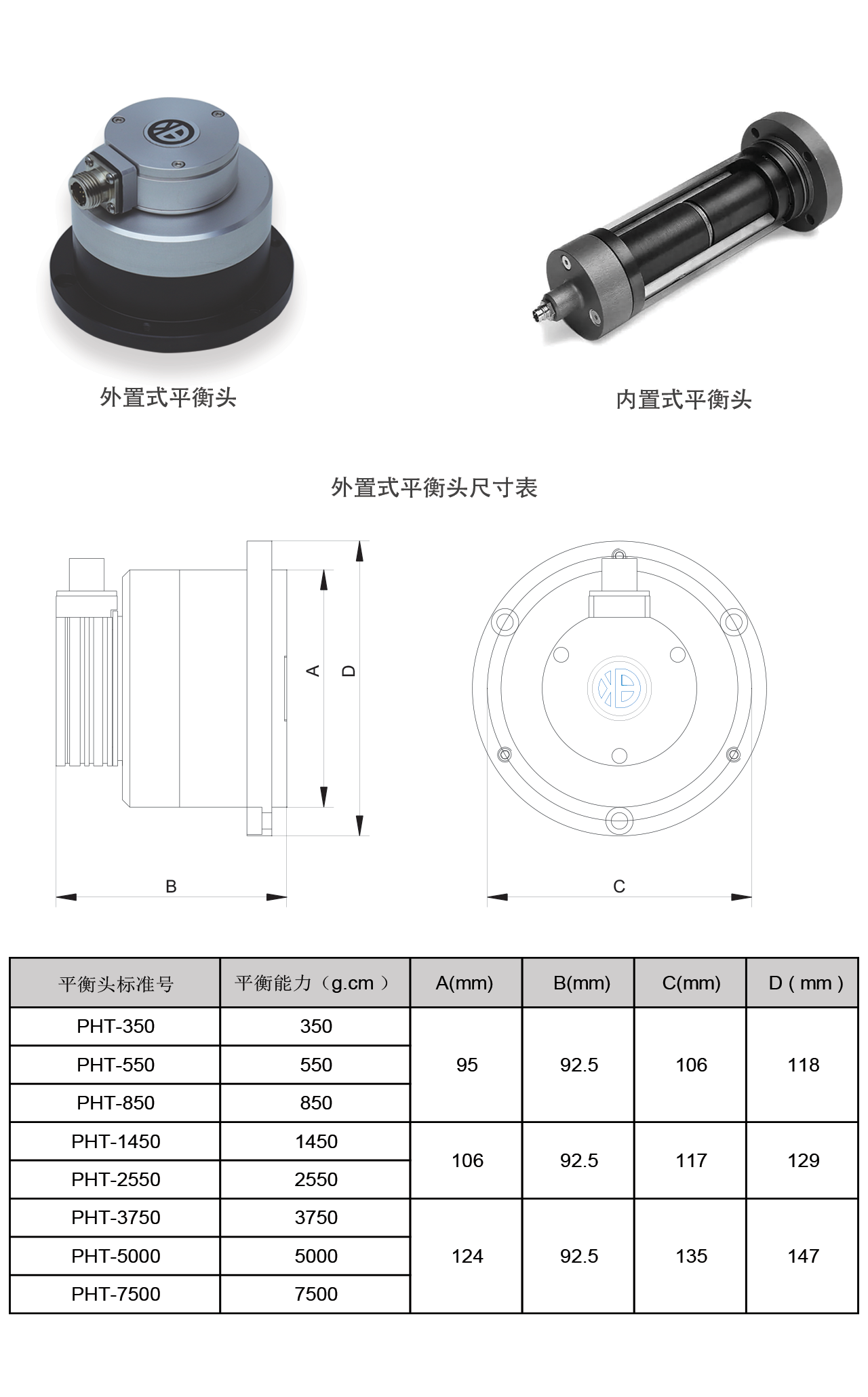

- Balance capacity range: 250-7500 g.cm

- Balance head type: support built-in and external

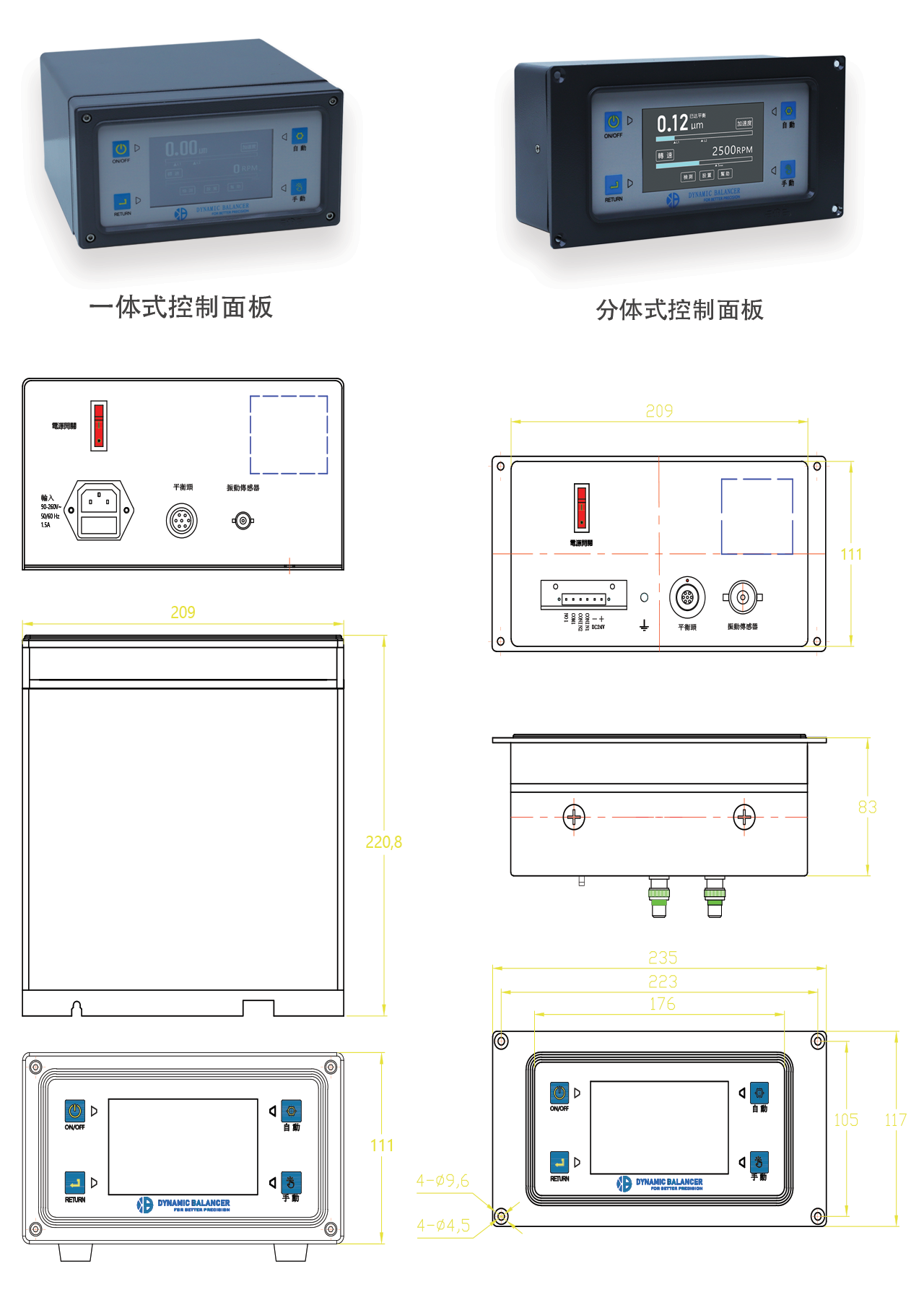

- Panel Type: One-piece (usually better for retrofits and retrofits)

- Vibration sensor range: 0-50 um

- Sensor accurate: 0.001 um

- Sensor Type: Vibration Acceleration Sensor

- Speed sensor: Hall type

- Power supply voltage: 220v

- Power type: AC AC

- Total equipment power: 50w

- Warranty period: standard 24 months

- Normal warranty: free inspection and repair

- Service Type: Guided Installation

Balance Head

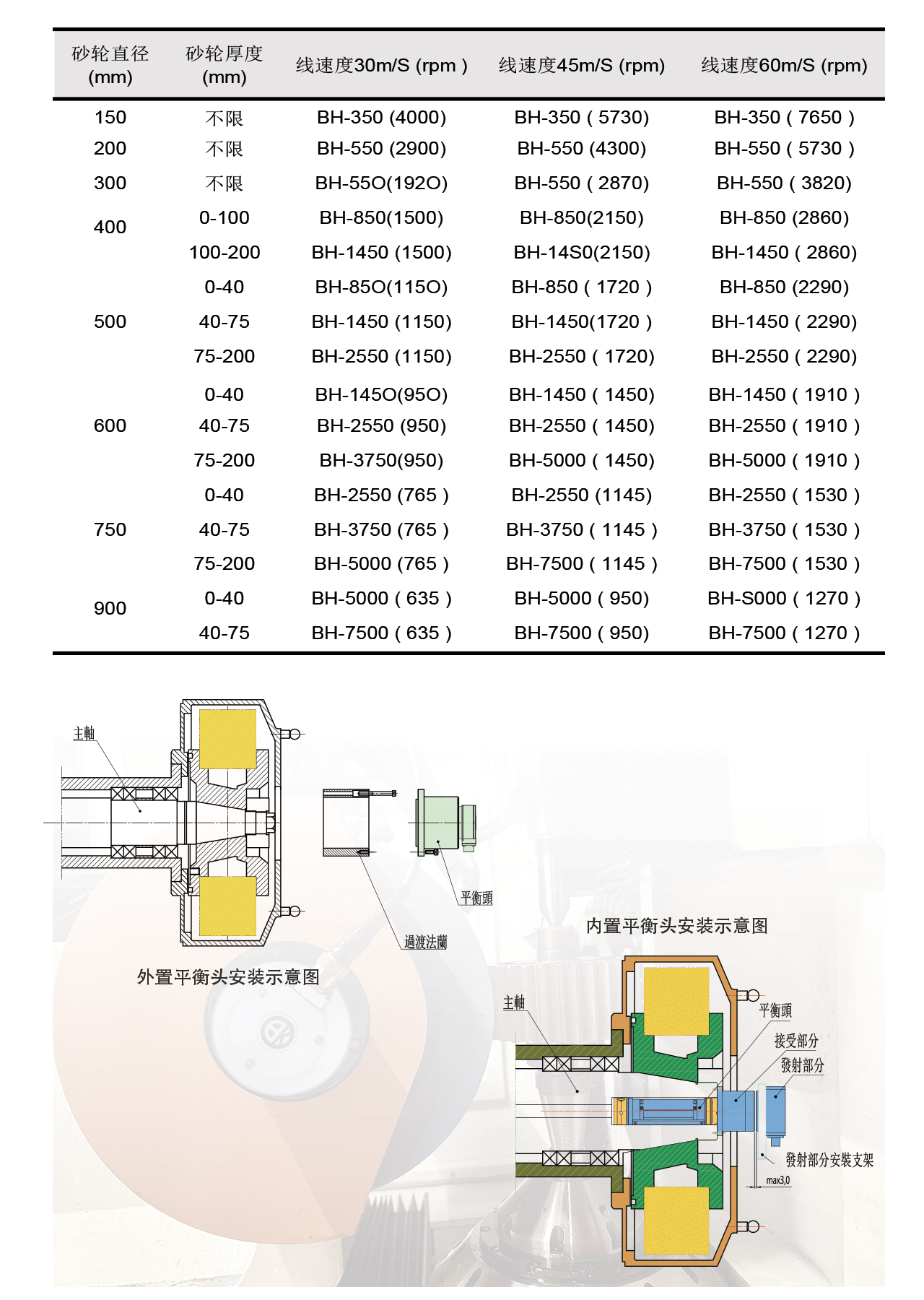

动平衡头选型

电控箱尺寸图

Videos Guide

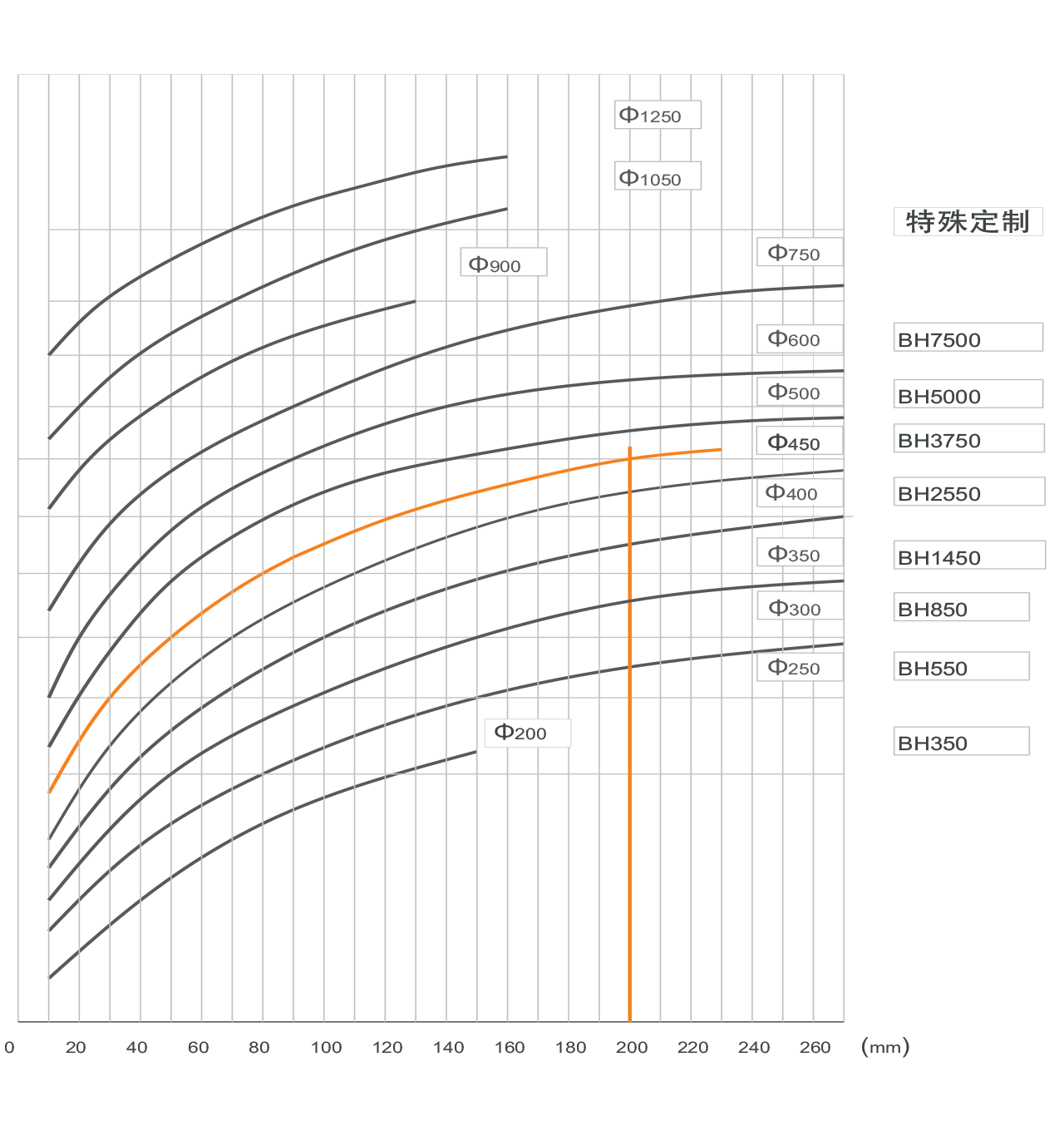

Performance Curve

Example: As shown in the staggered position of the yellow part in the above figure, it shows that the grinding wheel with a diameter of 450mm and a grinding wheel thickness of 200mm should have a balance capacity of about 3750g.cm. Of course, this also needs to be judged comprehensively according to the material and line speed. Therefore, please take the initiative to contact us when selecting the model, we will review the model selection according to the parameters you provide, thank you!

Because the built-in balancing head needs to be matched with the main shaft of the equipment, there is no standard size table provided. Users should contact our engineers when they need it.

Download center

Best seller

Portable Grinding Wheel Dynamic Balancing System

Contains 5 commonly used algorithms to solve 99% of rotor dynamic balancing needs in the market. Especially for the needs of grinding wheel dynamic balance, it provides single-point circumferential weight removal, two sets of balance sliders, three sets of balance sliders and proportional combined counterweight functions, which can quickly solve the needs of grinding wheel dynamic balance. It is the system that can best solve the dynamic balance of vertical mills on the market.

On-site dynamic balancing system

It can be used for almost any rotor in grinding machines, large fans, water turbines, textile machinery, etc. There is no need to disassemble the equipment for balancing (pipelines and other parts need to be disassembled for balancing operations). The original Sooner balancing technology can complete the dynamic balancing of the rotor in a very short time. A variety of balanced weight modes can meet your dynamic balance needs more conveniently.