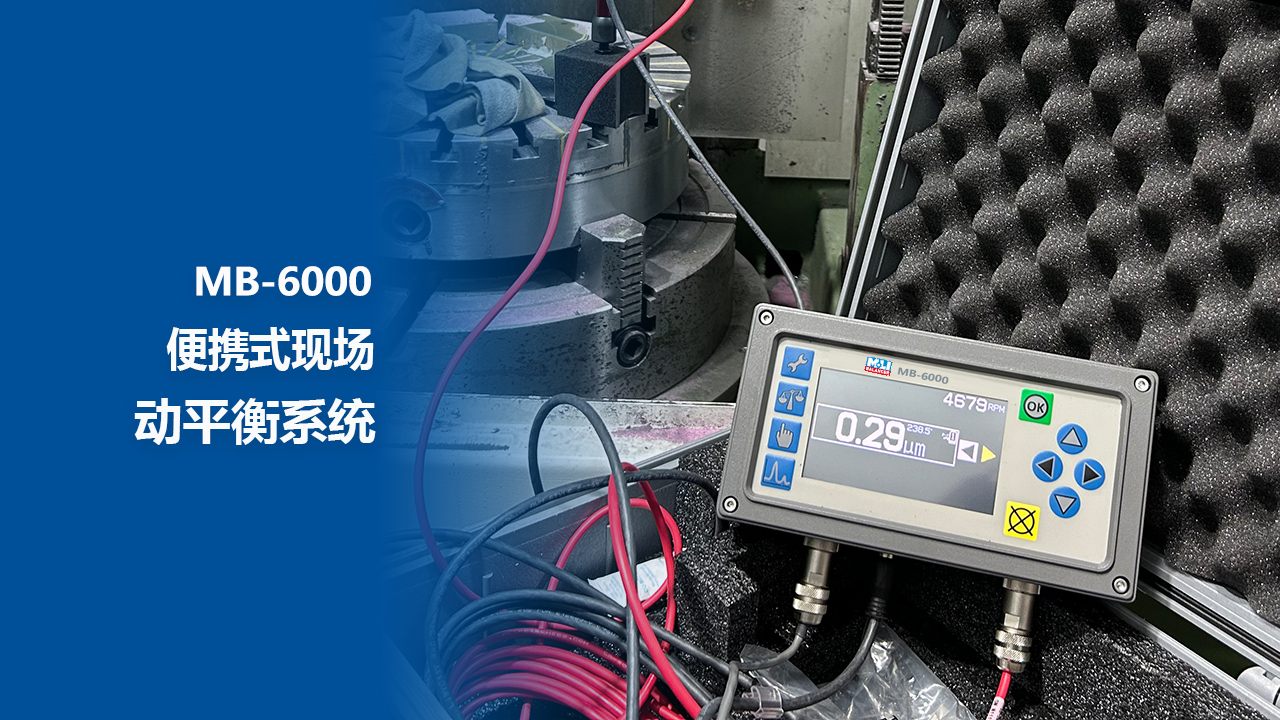

On-site dynamic balancing system MB-6000

On-site balancing is the dynamic balancing process carried out on the rotor itself on the shafting and frame, rather than on the dynamic balancing machine. In other words, at the work site or machine test site, the balance state of the rotor is not satisfactory, and the dynamic balance carried out by the vibration state of the machine operation must be improved, which is the on-site dynamic balance system.

Under such conditions, the data required for on-site balancing is obtained by measuring the unbalanced vibration of the supporting structure and rotor shaft caused by rotor imbalance. The mother of on-site dynamic balance is to make the mechanical vibration caused by unbalance, the dynamic deflection of the shaft and the force acting on the bearing reach the allowable value, so the evaluation of on-site dynamic balance is generally measured by the vibration standard of on-site machine operation.

Features

- Portable: A dynamic balancing system that is not limited by space

- Online measurement: complete dynamic balancing without disassembly and assembly

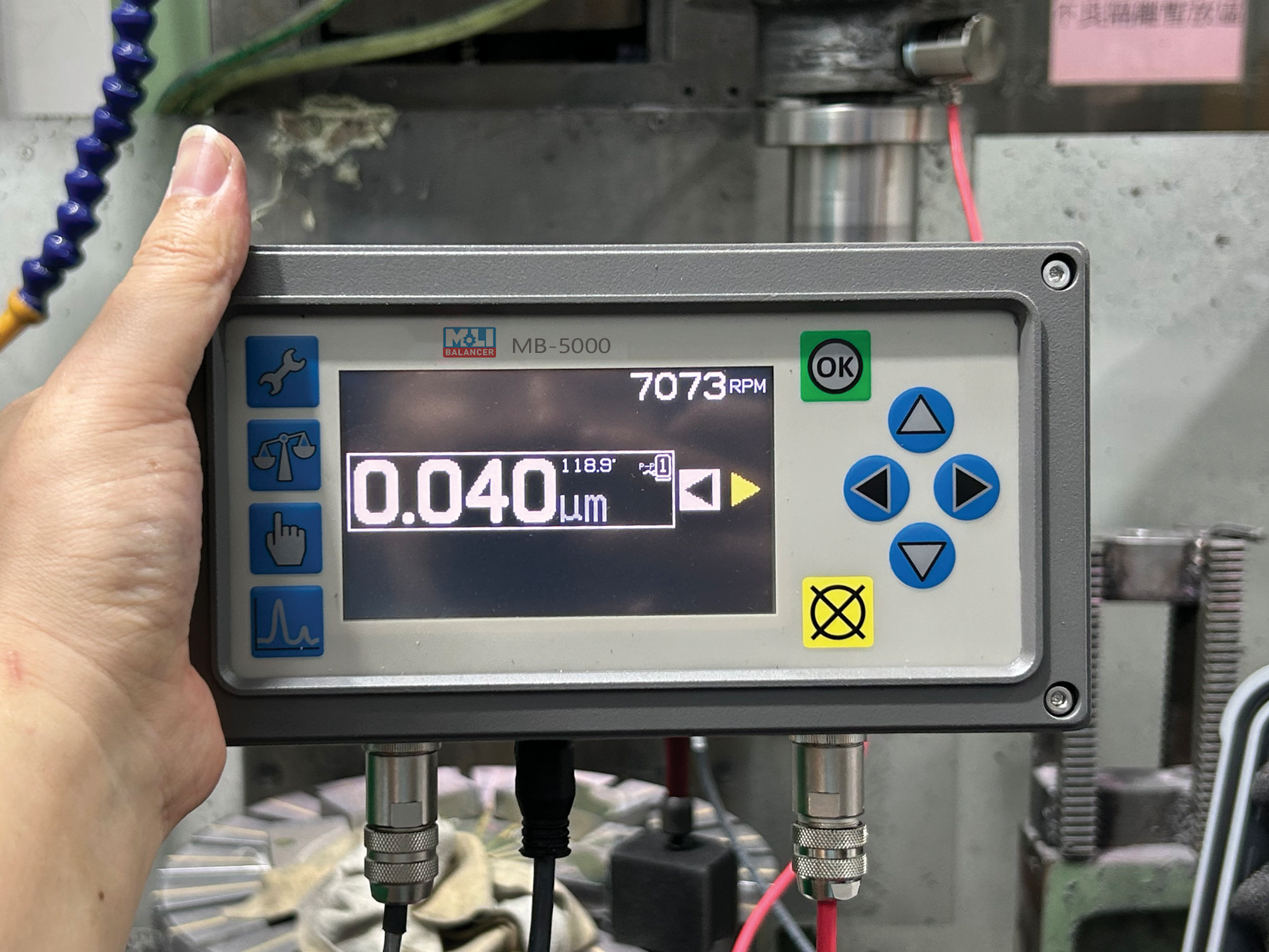

- High precision: can be accurate to 0.001um

- Ease of use: Interns and ordinary workers can get started at a glance

- Good versatility: 5 rotor adjustment schemes, suitable for almost all commonly used rotors

- High scalability: one machine in hand, the whole factory is worry-free

参数

A range of parameters to evaluate include:

- Balancing capacity range: can be installed and can be basically balanced

- Balance type: single-sided and double-sided

- Panel type: push-button type

- Vibration sensor range: 0-50 um

- Sensor precise: 0.001 um

- Sensor type: Vibration acceleration sensor

- Speed sensor: Hall type

- Speed detection range: 50-99999rpm

- Spectrum analysis function: Yes

- Power supply voltage: 220V

- Power supply type: AC AC

- Total equipment power: 50W

- Warranty period: standard 24 months

- Normal warranty: free inspection and maintenance

- Service type: Guided installation

Videos Guide

Videos

Download Center

Best seller Products

Portable grinding wheel balancing system

Contains 5 commonly used algorithms to solve 99% of rotor balancing needs on the market. Especially for the needs of grinding wheel dynamic balance, it provides single-point circumferential plus deweighting, two sets of balance sliders, three groups of balance sliders and proportional combination counterweight functions, which can quickly solve the needs of grinding wheel dynamic balance. It is the system that can best solve the vertical grinding balance on the market at present.

On-site dynamic balancing system

It can be used for grinding machines, large fans, water turbines, textile machinery and almost any rotor. There is no need for equipment disassembly (pipes, etc. need to be disassembled for balancing operations). The original Sooner balancing technology can complete the dynamic balancing of the rotor in a short time. A variety of balanced counterweight modes can more easily meet your dynamic balance needs.