Cylindrical Grinder Dynamic Balance Solution

Why does the cylindrical grinder system need online dynamic balance of the grinding wheel

If the grinding wheel is not dynamically balanced online, it may cause problems such as uneven grinding area, poor surface quality, and excessive grinding sound, which will affect the accuracy and efficiency of grinding, and even cause damage to the machine tool and safety accidents.

Therefore, in the cylindrical grinding machine system, the online dynamic balance of the grinding wheel is a very important technology, which can improve the grinding efficiency and quality, and ensure the normal operation of the machine tool and the safety of the operator.

Feature

- Very high balancing efficiency, the automatic system usually completes the dynamic balancing process within 0.5 minutes

- Portable, using the latest solution, usually 2-3 minutes to complete the balance

- High balance accuracy, accurate to 0.01um

- Convenient operation, touch and button combination

- Efficient integration with CNC systems

2 Choice for Grinding Machine Balance

Automatic Dynamic Balancing System

We can adopt a fully automatic dynamic balancing solution, one machine and one matching, to monitor nuclear balance at any time. Fully automatic, no need to manually adjust the balance weight. But because one machine is equipped with one machine, the cost is relatively high. For users who require both precision and efficiency, the automatic grinding wheel dynamic balancing system is the first choice

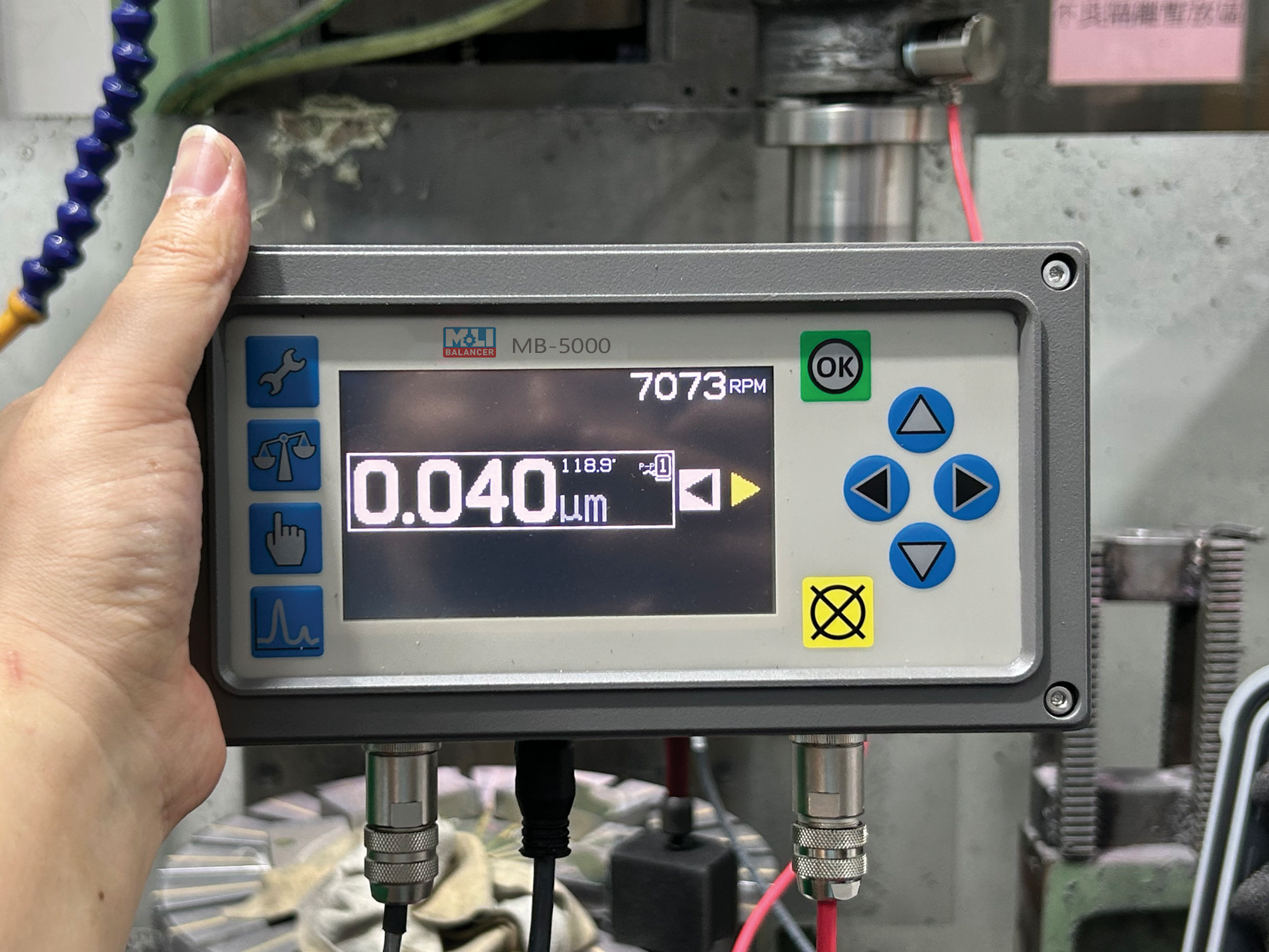

Portable Balancing Solutions

The portable grinding wheel online dynamic balancing system can be used for multiple purposes. It can meet customers who have general requirements for precision and a large number of machine tools. The upgraded dynamic balancing solution can expressly stabilize various rotors such as grinding machines, wind wheels, gears, and water wheels. And it can achieve ultra-high balance accuracy, especially for vertical grinders and mirror grinders, there are unique balance solutions. Can solve user problems faster.

两种方案的比较

| Balancer Type | Auto on-site balance system | Portable On-site balancer |

| Weight adjust | Auto adjusted by DC motor | Hand adjust |

| Balance accuracy | 0.01um | 0.001 um |

| balance speed | in 1 min | in 3-5 mins |

| Applicable speed | 450-9000 rpm | 300-99999 rpm |

| Speed Detection | Hall type speed sensor | Infrared speed sensor |

| portability | Fixed installation | Portable |

| Assembly method | One machine needs to be equipped with one | Balance multiple machines |

Download Center

Hot Sale Balance System

Portable Grinding Wheel Dynamic Balancing System

Contains 5 commonly used algorithms to solve 99% of rotor dynamic balancing needs in the market. Especially for the needs of grinding wheel dynamic balance, it provides single-point circumferential weight removal, two sets of balance sliders, three sets of balance sliders and proportional combined counterweight functions, which can quickly solve the needs of grinding wheel dynamic balance. It is the system that can best solve the dynamic balance of vertical mills on the market.

On-site Dynamic Balancing System

It can be used for almost any rotor in grinding machines, large fans, water turbines, textile machinery, etc. There is no need to disassemble the equipment for balancing (pipelines and other parts need to be disassembled for balancing operations). The original Sooner balancing technology can complete the dynamic balancing of the rotor in a very short time. A variety of balanced weight modes can meet your dynamic balance needs more conveniently.